Case1—— Carbon fiber SMC system, Designed for lightweight automotive parts

Molding process: carbon fiber SMC molding

Resin type: Ecoleader® EL6810Series

Fiber content: >50%

Molding cycle: <1min/mm

specific gravity: 1.45g/cm3

Features: Ecoleader® EL-6810 series is a modified vinyl ester resin system developed for carbon fiber SMC.Reliable thickening is very suitable for C-SMC formula with high fiber content and low filling, providing excellent flowability for carbon fiber SMC molding.The high efficient curing speed can meet the requirements of the production cycle time of the automotive industry.By improving its binding with fiber, it can improve its strength, reduce its density, and finally make its weight loss more efficient.

Case2——SMC resin system for high surface quality automotive exterior trim

Molding process: SMC molding

Resin type: Ecoleader® EL-6138 SYSTEM

Molding cycle: <1min/mm

Shrinkage rate: -0.05%

Features: EL-6138 resin system produced by SMC molded auto parts, can achieve A class surface quality, while providing high quality and reliable parts products, but also can greatly reduce the labor cost and environmental pollution caused by the post-treatment.

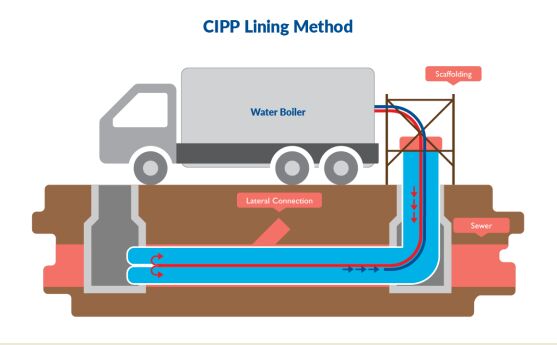

Case3——Relining used in pipe Trenchless repair

In - place solidification of the pipe to relining

The relining material is attached to the existing damaged pipe through the manhole to avoid the road collapse caused by the damaged pipe.Compared with the traditional excavation method, this technique not only saves the cost but also improves the efficiency.In addition, the new relining improves the corrosion resistance of the downpipe and has a long service life.

Process: relining - water turning process

Resin Name: Ecoleader® EL-5033

Chemical type: Iso- resin

perties: High Modulus, Good Toughness, Good Corrosion Resistance, and has a very good wetting and binding to the fiber.

Case4——Seawater-resistant and wave-resistant pultrusion resin, Marine nori cultivation pole

Making Process: Pultrusion

Resin type: Ecoleader® EL-400

Resin type: Iso-phthalic resin

Properties: good water resistance, good toughness, good at pultrusion process, and has a very good fiber wetting and binding.

In traditional nori cultivation, bamboo has been used to insert into the sea floor and hang the cultivated nori seedlings.Bamboo generally used less than two years on the rotten fracture, the need for constant replacement;And its length is limited, it cannot be expanded to a certain depth of the sea, and its low strength and rigidity can not withstand the waves of the open sea.These problems can be solved by using EL-400 pultrusion glass fiber composite poles.After 5 years of seawater immersion, wave impact and natural aging, the poles produced by EL-400 still maintain a bright appearance, and the actual breaking rate is very low.

Zhenjiang Leader Composite Co., LTD 苏ICP备20033322号 Office: Floor3,Building7,Jiangsu Geographic Information Industrial Park at No.18 of North Lingshan Road,Qixia District,Nanjing City,Jiangsu Province . Plant add: Dantu Developing Zone,Zhenjiang,Jiangsu province EMAIL:xiefuping@njleader.cn